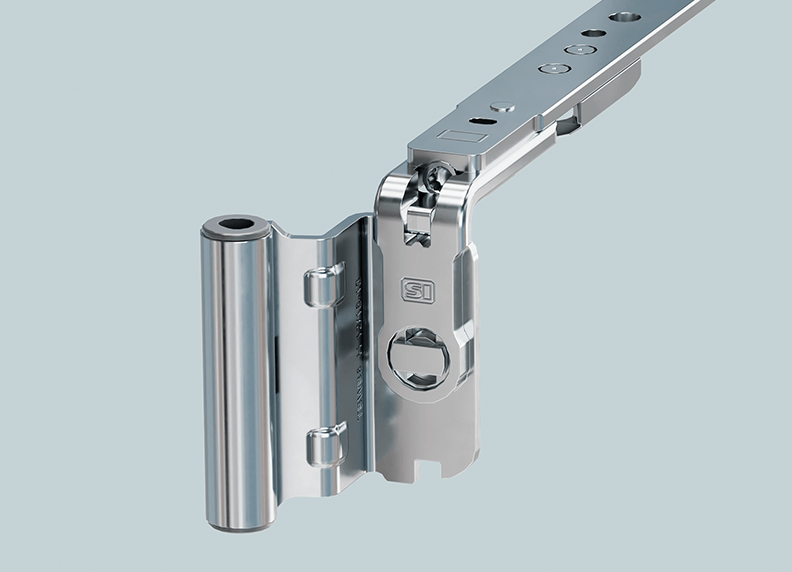

TITAN Timber Hinge Side now even stronger

The optimised hinge side from SIEGENIA provides new advantages for fabricators and end users

Time and cost savings in production – permanently satisfied customers: The further development of the TITAN Timber Hinge Side from SIEGENIA stands out thanks to new advantages for fabricators and end users. The hinge side is suitable for timber systems up to 150 kg sash weight and ensures a high degree of security with an intruder resistance up to RC3. The successful testing in the durability class H3 (DIN EN 14126-8) verifies an extremely long service life with 20 000 cycles. From end users' perspective the new hinge side also scores points thanks to its lean, modern design and its subtle look with concealed screwings, cover caps in different colour variants and new optional coatings.

Clear gains in production efficiency

Fabricators will benefit from the further development of the TITAN Timber Hinge Side thanks to clear efficiency gains in production. The innovative and positive locking stay hinge coupling which no other company but SIEGENIA is currently offering contributes to this. This ensures an easy, reliable stop in the DIN direction. The totally new type of bottom hinge bolt fastening for convenient stops and attachment of the sash as well as the innovative turn-tilt stay are time and cost saving too. It guarantees first-class sealing and an effective pressure adjustment. From the fabricators' perspective a new turn only sash stay which is cut to length is also impressive.

The new hinge side owes the reduction in warehousing to its suitability for use up to 150 kg sash weight, the high capacity compact stay and the stay hinges independent of DIN. The advantages of the TITAN Timber Hinge Side are topped off with a consistent turn restriction, compatibility with different threshold systems and the possibility of realising TBT sashes.

A whole host of advantages with the TITAN fitting technique

As part of the TITAN hardware family the Bandseite TITAN Timber Hinge Side stands for time and cost savings in production. That starts with the harmonisation of the cycle times and ranges from an efficient nut clamp to the click-on coupling point. Thanks to the easy sliding under the corner drive and its insensitivity to production tolerances the click-on coupling point ensures greater efficiency in assembly on the completed sash. TITAN hardware also provides cost-effectiveness thanks to its kit with short and long components. The latter achieve a hinge side structure without extension parts.

The comfort mushroom cam has also been setting standards with its self-activating, continuous height adjustment of up to 2.5 mm. It ensures an automatic compensatory tolerance of the airgap of 10–15.5 mm, secures the adjustment position and in this way achieves a high degree of sealing and permanent ease of movement. Versatility is also a major feature of TITAN. The three different designs for the integration of sash lifters into the tilt points guarantee a high degree of flexibility in the realisation of customer requirements.