More than 100 years of experience.

For the room comfort of the future.

The SIEGENIA GROUP develops solutions that bring spaces to life. Our solutions for windows, doors and sliding doors focus on creating healthy, comfortable and smart spaces that give people a sense of well-being. Ventilation and smart home systems also contribute to this. KFV Karl Fliether GmbH & Co. KG covers the entire field of modern locking systems for doors. Our complete range is rounded off by SIEGENIA-AUBI Sicherheits-Service GmbH: with products and services concerning burglary protection and window repair.

The prospect of new room comfort is the theme of the future. We need the past to be able to design both sensibly and responsibly. Because tradition is the ideal basis for sustainable innovation. Even if we didn't call it "room comfort" before, we have been working on this for over 100 years.

The SIEGENIA History

2024

As a member of the Connectivity Standard Alliance (CSA) SIEGENIA with its smart products is focusing on Matter enabled solutions. With the launch of the smart window handle SIEGENIA is entering the Matter compatible Smart Home world of the future.

2024

The Fensterbau Frontale 2024 provided the appropriate setting for the presentation of individual EPDs (Environmental Product Declarations) by the ift Rosenheim. As a result, SIEGENIA is the first hardware manufacturer that has individual environmental product declarations which provide precise and reliable numbers for the CO2 footprint of SIEGENIA products. With the issue of these EPDs the company underscores its leadership role in the industry.

2023

The digital customer advisory tool SIEGENIA world is going live and showing with appealing animations the appearance, workings and design variations of the SIEGENIA products in detail. The product animations are running in virtual three-dimensional rooms. The innovative advisory tool wins an award at the Vienna Window and Sun Protection Congress.

2022

SIEGENIA-AUBI Sicherheits Service GmbH is moving from Reinsfeld to Wadern, Saarland. The new property which is located at about 25 kilometres from Reinsfeld provides optimal conditions for SASS in terms of location, square footage and facilities. Every SIEGENIA spare part can be warehoused here and delivered to customers within one to two business days.

2022

PORTAL product group expands production capacitiesThe continually growing PORTAL product group needs more space for the expansion of its production capacities and takes over the premises of SIEGENIA-AUBI Sicherheits-Service GmbH in Reinsfeld at the end of 2022. The logistics and the assembly of PORTAL compact parts are now concentrated here while the main focus of production at the PORTAL site Hermeskeil lies in the production of the COMFORT UNIT and the machining of long parts.

2020

ECO PASS SKY axxent receives Red Dot AwardThe ECO PASS SKY axxent barrier-free threshold from SIEGENIA was awarded the "Red Dot: Best of the Best 2020" prize for its pioneering design. Only about 1 percent of more than 6,500 objects submitted by a total of 60 nations have received this award. It is exclusively awarded for revolutionary solutions by the jury, consisting of international experts in diverse specialist fields.

2020

SIEGENIA recognised as a family-friendly companyThe Frau & Beruf Siegen Wittgenstein Competence Centre recognised the Wilnsdorf-Niederdielfen site as a family-friendly operation. With flexible working hours, part-time training and childcare of children of employees in the company's own daycare centre, SIEGENIA scores points in the certification process.

2019

SIEGENIA online shop goes into operationThe starting signal for the SIEGENIA online shop is fired. The first product available for order is the PORTAL HS COMFORT UNIT (CU) - the customised "zero-hassle package" for large elements. The new SIEGENIA online shop makes ordering and configuration even safer, faster and easier.

2019

SIEGENIA continues to invest in productionA new production department for PVC components is set up at the Niederdielfen site. The state-of-the-art, energy-efficient production and assembly plants strengthen the production and logistics processes of the company and demonstrate the company's commitment to the German site.

2018

KFV has written a success story with innovative locking technology for doors. Now the subsidiary of the SIEGENIA GROUP starts its anniversary year: in 2018, KFV proudly turns 150. With several new and further developments, the German market leader of multi-point locking systems documents its continuing innovative strength and is today one of the leading lock manufacturers in Europe.

2017

Founding of SIEGENIA INDIA PRIVATE LIMITED in New Delhi.

2017

New construction of a production hall in the Poland plant. This means there is now 14,500 m2 of production and storage areas available, including a workshop and office building with social rooms.

2016

New warehouse for PORTAL hardwareThe continuing high demand for sliding hardware and the resulting growth of the PORTAL product group necessitate the building of a new warehouse: the storage capacity at the Hermeskeil site is increased considerably by 1,100 square metres.

2016

SIEGENIA is bringing the new surface centre on stream at the Niederdielfen site. The state-of-the-art electroplating unit is systematically designed for sustainability and energy efficiency.

2015

Successful launch of the new brand image with an emotional campaign, which focuses on the user benefits – and therefore makes it possible to experience room comfort.

2015

The new slogan underlines what has always been an integral part of our product philosophy: SIEGENIA is room comfort. Because with our products and solutions we bring spaces to life and give people a sense of well-being.

2015

SIEGENIA sets up a PartnerNetwork. It includes the provision of promotional materials and product documentation, training and a listing in the end user supplier search.

2014

The SIEGENIA story stretches back 100 years. The motto and logo on the 100th birthday "More drive than ever" underscores the dynamics of the company and also points to the new product spectrum embracing the smart world.

2014

The current new construction of an exhibition centre with integrated test centre, together with the building of a state-of-the-art surface treatment plant in Niederdielfen are an indication of the company’s continuous modernisation process.

2014

SIEGENIA-AUBI Sicherheits Service GmbH is relocating its company headquarters and moving from Hermeskeil to neighbouring Reinsfeld.

2014

At the main site in Niederdielfen, SIEGENIA opens a company daycare facility. Its purpose is to make it easier for employees to return to work and to further increase the number of women in the workforce and in management positions.

2013

SIEGENIA is introducing the 2nd generation of the fully motorised GENIUS multi-point lock to the market. With the A-opener the company has also developed an electromechanical retrofitting solution for automatic multi-point locking systems which can be ideally connected to the digital KFVkeyless access control system and as a result, controlled via the keypad or the smartphone.

2011

SIEGENIA is building a new production site at Sanhe near Beijing.

2008

2008 is the year in which the SIEGENIA-KoPiBo (3D-ComfortMushroomBolt) begins its triumphant march through the TITAN AF hardware range. As the result of its flexible height adjustment, the KoPiBo always compensates for airgap tolerances perfectly and thus reduces adjustment time considerably. Window installers are delighted by it and window users appreciate how easy the smooth-running window is to use.

2008

SIEGENIA-AUBI is the first hardware manufacturer in the world to get the ift Q-certification mark.

2008

SIEGENIA is launching a sales office in Istanbul.

2007

All components that are not cut to length have the new ”Click-Coupling Point“ This coupling point enables linkage and extensions to be installed very quickly. These components are simply pushed in and the coupling point snaps in automatically.

2006

2006 SIEGENIA acquires the German market leader for high quality door hardware and locking systems, KFV Karl Fliether GmbH & Co. KG in Velbert. This acquisition completes the product range of SIEGENIA, making the company one of the leading providers of integrated solutions and systems for window and door functionality, and the decentralised ventilation of rooms.

2005

The ventilation technology product group moves to the Lehnscheid site in Wilnsdorf.

2004

From Safety Plus GmbH founded in 2001 the company became SIEGENIA-AUBI Sicherheits-Service GmbH (SASS for short) in 2004. SASS has been successfully specialising in products, solutions and service features involving the retrofitting of previously installed windows with anti-burglary protection and window repair.

2004

In Poland SIEGENIA-FRANK Polska (Poznan) and AUBI Polska (Kluczbork) are amalgamating under SIEGENIA-AUBI KG. Both sites are consolidating at the Kluczbork production site.

2003

Five years after the acquisition, AUBI Baubeschläge GmbH and SIEGENIA-FRANK KG are merged to form the existing SIEGENIA-AUBI KG.

2002

SIEGENIA is introducing a new innovation to the market, which is revolutionising the production process in window manufacturing: The TITAN iP hardware system makes it possible for the first time and very flexibly to assemble hardware components on the profile bar or the scantling before welding or bonding.

2001

To be able to service the rapidly growing markets in China and Southeast Asia, SIEGENIA is launching a China subsidiary in Beijing in 2001.

1999

In 1999 SIEGENIA introduce a further innovation in the form of the first parallel window hardware (PAF). The window sash can be partially opened parallel to the frame for night ventilation and the window is also intruder resistant to RC2 in the night ventilation position.

1998

And from AUBI a development emerges, which is now an industry standard: the so-called “sash lifter”, which continues to lift the window sash even when sashes start to drop over time as a result of their own weight.

1998

With the acquisition of the AUBI Baubeschläge GmbH in Hermeskeil (Rheinland-Pfalz) in 1998, Wieland Frank expands the product and customer portfolio, thereby laying additional and important foundations for the growth of the business in international markets.

1996

With the opening of its own sales office in Italy, SIEGENIA is strengthening its presence in Southern Europe. From here, customers and partners will be supported directly to meet the growing demand for innovative hardware solutions in the Italian market even more efficiently.

1996

With the relocation of the head office from Kaan-Marienborn to the new building in Wilnsdorf-Niederdielfen, the consolidation of administration and production into Niederdielfen – today’s headquarters – is complete. The timelessly modern and exceptional architecture of the new building wins an award from the Association of German Architects in 1997.

1996

SIEGENIA has been augmenting its activities in Poland since 1996. With the establishment of SIEGENIA-FRANK Polska with headquarters in Poznan the company would like to satisfy the growing demand for SIEGENIA hardware in Eastern Europe.

1994

The double-cup routing for corner and top hinges in timber windows – already prepared in the profile – facilitates painting and the positioning of the pivot point components as well as screw fixing.

1989

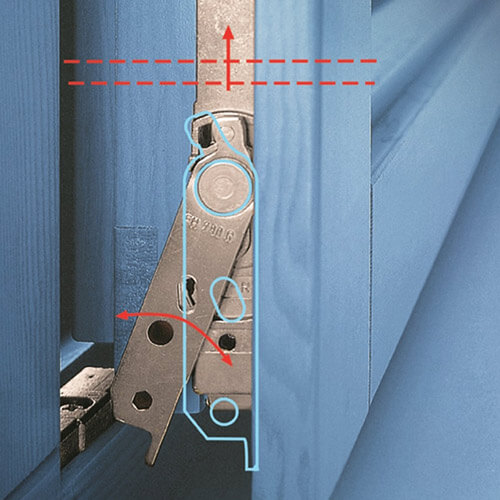

The family business sets further industry standards in terms of streamlined window production in 1989, with the introduction of the first clamp-on turn and tilt hardware for aluminium profiles.

1989

In the wake of political upheaval in Germany and Eastern Europe following the fall of the Berlin Wall in 1989, the company increases its expansion into other European countries, as well as into markets in the Middle and Far East. Eleven sales and distribution sites are established and the existing ones are expanded.

1988

The move from the third to the fourth generation occurs unexpectedly in 1988, as Gerhard Frank dies in the October of this year following a serious illness, aged 68. His son, Wieland Frank, aged 29, takes over the reigns of the family business, becoming managing director and personally liable shareholder.

1987

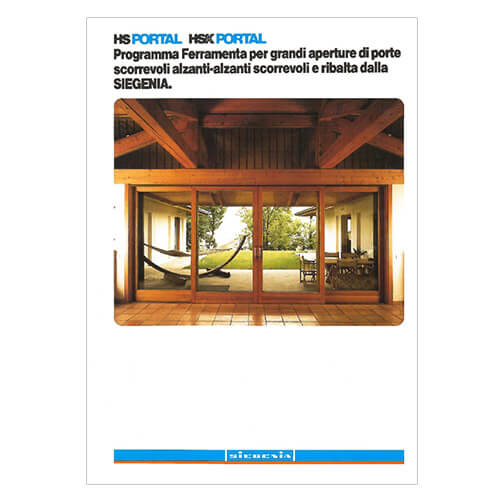

PSK PORTAL is the response to the demand for greater assembly efficiency, for greater operating convenience and for greater security. The first tilt and slide fitting, which can move sash weights of up to 150 kg is launched on the market.

1984

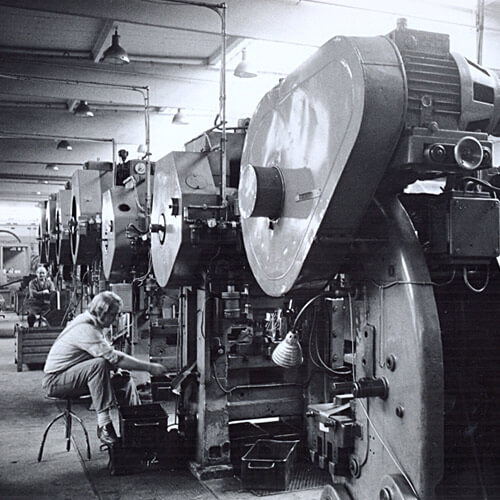

In a further section of the building, a new wing with an area of 4000 m2 is put into operation. With a total 29,000 m² of production and warehousing space, the most modern manufacturing facilities provide conditions for ensuring consistent quality. The company employees 700 people and exports more than 20% of its products.

1983

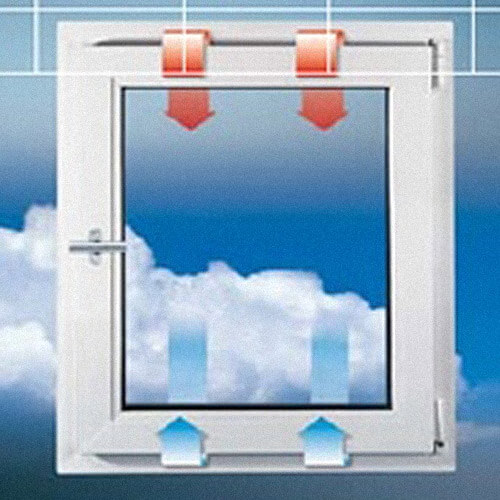

The SIEGENIA AEROPAC is a high-performance and energy-saving wall ventilator, which keeps road, rail and air traffic noise pollution outside, whilst providing a supply of fresh air even with windows closed.

1982

With around 1300 m2 of floor space, the new staff building is opened. In addition to a kitchen and dining room and a training room on the ground floor, washing and changing facilities are located in the basement.

1981

At the start of the 1980s, the product range is expanded to include lift and slide hardware for large sliding windows and doors, and also sound-insulated ventilation.

1978

Thousands of fittings leave the new Plant II in Niederdielfen daily and soon additional production facilities are needed. The production halls in Niederdielfen continue to be extended gradually up to 1984. Fortunately, the two oil crises of 1973 and 1979 interrupt the growth of the company only briefly.

1974

At the start of 1974, the finished-products warehouse, packing and dispatch are relocated to plant II in Wilnsdorf-Niederdielfen.

1973

In 1973 SIEGENIA presents the “trial gear”, setting new standards in window production: firstly, the retaining pocket for the lock case of the gear is produced in one drilling process and no longer requires the time-consuming process of having to be routed into the rebate. Today, both the component concept and the gear drilling are standard on turn and tilt hardware.

1972

On 1 April 1972 the first sales office is opened in Eugendorf near Salzburg (Austria).

1972

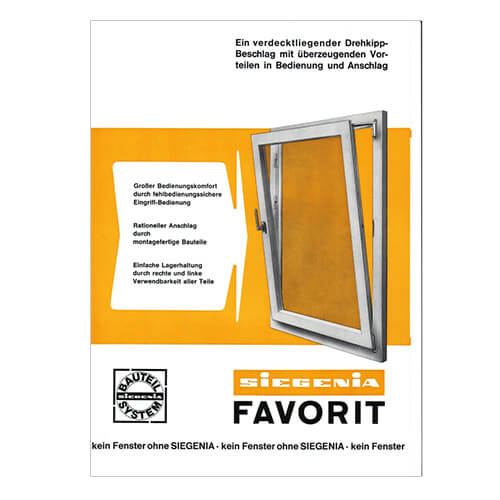

With the development of the turn and tilt fitting, FAVORIT, of which over 250 million have now been sold, SIEGENIA provides key fabrication benefits for modern window production. For the first time, SIEGENIA launches a fitting that enables the window manufacturer to give windows the “turn and tilt” function in just a few steps, using a manageable number of hardware components that can be easily combined.

1970

In the same year, he receives the Order of Merit of the Federal Republic of Germany for services to business.

1970

In the meantime, SIEGENIA has become such a famous brand that, in 1970, Gerhard Frank renames his company SIEGENIA-FRANK KG.

1969

The GLOBAL: single operation turn and tilt fitting with “all-round locking”, consisting of pre-assembled components.

1968

The SIEGENIA-COMPACT turn and tilt fitting, which sits on the sash rebate, comprises of just two pre-assembled components form: this simplifies installation considerably and gives the sash greater stability.

1967

The second plant opens in the new Weißtal industrial area of Niederdielfen. The new production facilities here include a modern electroplating system and part of the administration.

1966

Jäger-Frank KG produces the first single operation turn and tilt fitting for aluminium windows with the LM 1000.

1964

1964 sees 50 years of “Jäger-Frank KG Hardware for the Construction and Furniture Industries“ being celebrated.

1964

1964, the same year as his father dies, Gerhard Frank receives the Diesel gold medal for numerous inventions.

1962

In the following years the company grows rapidly: 1962 sees the acquisition of a new administration building in Eisenhüttenstraße. JÄGER-FRANK KG now employs over 200 people

1961

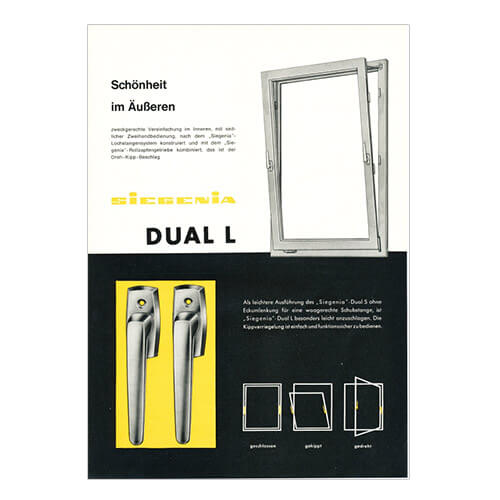

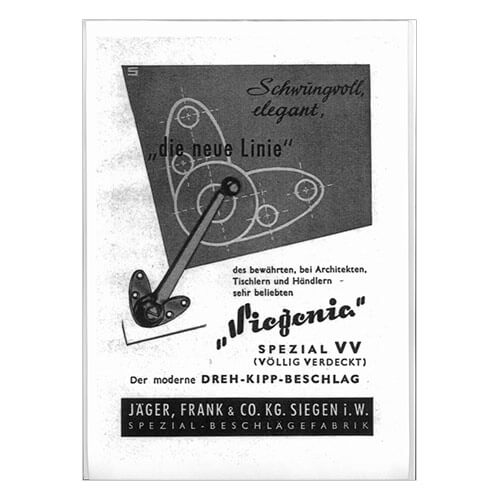

The SOLID, DUAL and VARIANT hardware represent the new generation of concealed turn and tilt hardware from the SIEGENIA company. All three types of hardware are based on a concealed push rod mechanism. The difference between the three types is the location of the operating handle: on the lower sash bar (VARIANT), above the corner gear (SOLID) or laterally centred on the window sash (DUAL).

1958

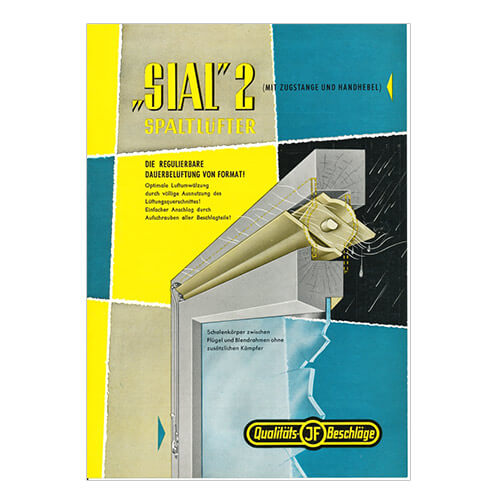

With the SIAL, the first night ventilator for windows, which is operated via handle and pull rod, is launched on to the market.

1957

As personally liable partner, Gerhard Frank becomes co-owner of the SIEGENIA company.

1955

1955 was the year that the SIEGENIA brand was officially born. The name – which had already been in use since the end of the war – is registered as a trademark with the German Patent Office.

1955

And just one year later, the first concealed turn and tilt fitting appears. Fully integrated in the window frame, it renders the mechanism of the turn and tilt window invisible and thus fulfils contemporary architectural requirements.

1954

The first non-handed turn and tilt fitting captures the market in 1954 and gives the company a distinct competitive edge. ”Turn & tilt“ describes both functions of the window, which allow it both to open and to tilt for ventilation.

1952

The expansion of the company is closely linked to the Federal Republic of Germany’s “economic miracle” and is based primarily on the window ventilation hardware product range, which is sold under the name of SIEGENIA at home and overseas.

1949

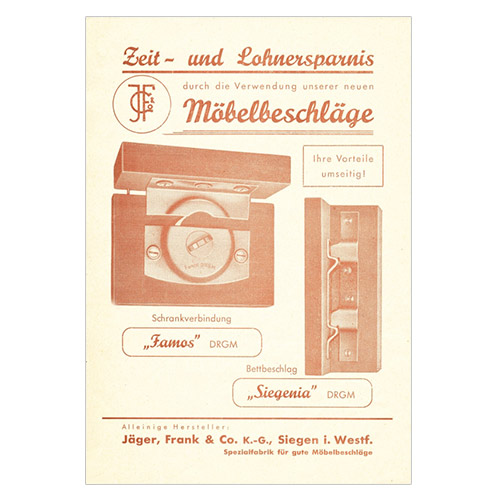

In 1949 new screw-on furniture fittings were launched, which no longer had to be set into timber. These included the FAMOS cupboard fitting and the SIEGENIA bed fitting.

1945

Gerhard Frank (1947-1988) returns from captivity as a prisoner of war and enters the company on 1 July 1945. With the spirit of innovation, openness and persistence, Gerhard Frank moulds the small family business into an international organisation under the experienced eye of his father, Adolf Frank.

1945

Together with his son, Gerhard Frank, who returned from the war in 1945, Adolf Frank succeeds in rebuilding the company that was badly damaged in the war.

1937

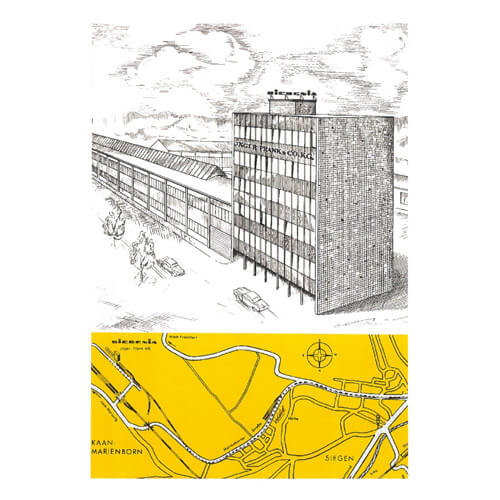

After the retirement of Wilhelm Jägers, the company becomes the limited partnership JÄGER, FRANK & Co. KG. Adolf Frank is now the only managing partner.

1937

However, the 1920s and 1930s were marked not only by an economic upturn, but also by setbacks, and so it turns out to be the right decision of Adolf Frank - who becomes sole managing shareholder of the Jäger-Frank KG in 1937, by then a limited partnership - to gradually switch production to modern window ventilation hardware.

1919

At the end of the war, his son-in-law, Adolf Frank, enters the fledgling company as managing director, which is then known as JÄGER, FRANK and Co. GmbH. It is now that the company begins to successfully manufacture furniture fitting and hardware; and due to his training in the fittings industry both at home and abroad, the young Adolf Frank had valuable experience in this field.