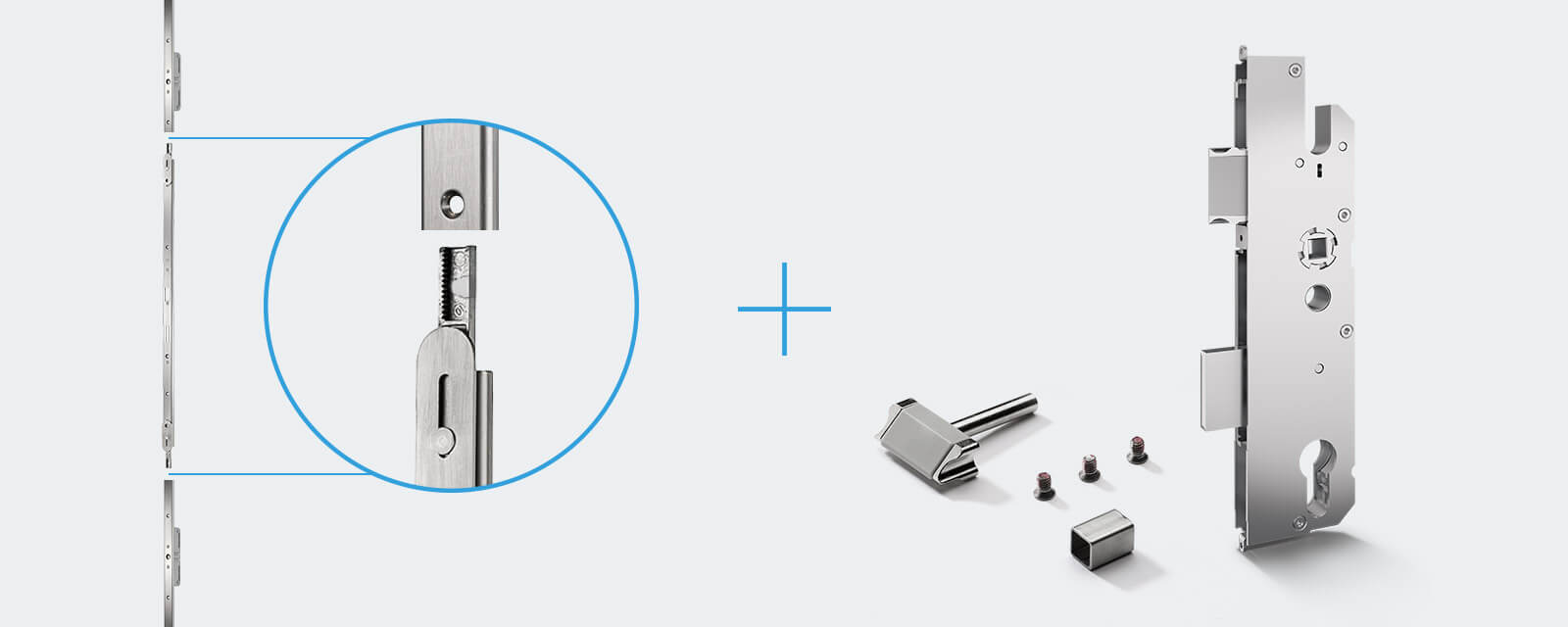

Multi-point service lock

for key and handle-operated solutions.

A quick solution for defective front doors independent of manufacturer.

The multi-point service lock is the ideal solution to quickly repair and maintain front doors for homes and apartments, as it is a system that can be used with products from different manufacturers. With this, a wide range of key and handle-operated multi-point locks from KFV or other manufacturers can be replaced both easily and economically. Because the modular designed sets ensure flexibility in installation and reduced warehousing. KFV multi-point service locks are available for comfort mushroom cams, round bolt, hook bolt or round bolt - hook bolt combinations and for all conventional door heights. Handles can be installed in any position.

Identical faceplate sets with main lock sets

can be combined with diverse backset dimensions.

Possible with all lock types.