"Experiencing Technology Live": great holiday activity from SIEGENIA

Delighted by their very own pizza cutter

Anyone can buy a pizza cutter – to make a pizza cutter, however, needs to be learned: In an exciting project SIEGENIA invited school students from the region to grapple with technical topics in a very fun way. Under the motto "Experiencing Technology Live" the Siegerland company participated in this year's Wilnsdorf holiday events, now for the third time. For an entire morning at its headquarters in Wilnsdorf-Niederdielfen SIEGENIA provided the youngsters an entertaining and practice-oriented insight into the company and its technical careers. In addition to the two days in the course of the holiday programme the company also launched an extra taster day for the children of its employees.

Pizza cutter made by themselves

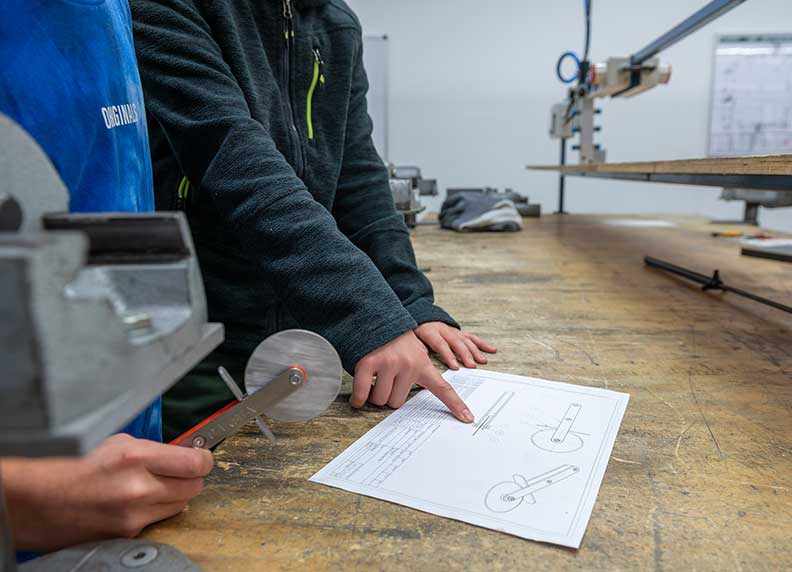

In all, 18 children and young persons took advantage of the opportunity to dive into the world of technology in a playful way and in the process to get initial reference points along the path of subsequently choosing a career. SIEGENIA had come up with something special in this regard: The centrepiece of the day of the event was the making of one's very own pizza cutter. "That the students were able to work with genuine original stainless steel components which our production no longer needed really clicked with them," recounts Sven Wiechmann, Technical Training Supervisor at SIEGENIA. "It was also important for us to set an example of sustainability by this means. This struck a chord with the young folks as well."

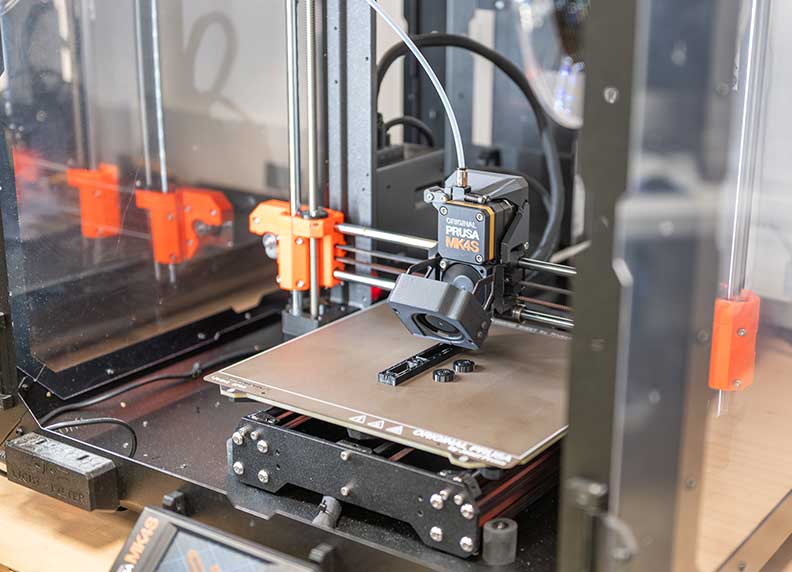

They were assisted in this by the technical trainees who, demonstrating their commitment in a big way, lent the youngsters their support. Within the context of the holiday activity they got the chance to deal with the participants independently for the first time and to guide them through the separate stations. They guided them step by step through the individual production stages, demonstrated the use of the machines and ensured fun but also the safety required during the implementation. From the classic metalworking by hand by drilling, filing and sawing to the 3D printing for handles and special parts to the stamping of a SIEGENIA logo on the workpiece they provided the students with loads of tips. A valuable experience for the trainees too: In this way they were able to practise within the framework of the activity assuming responsibility at an early stage, supervising a small project and imparting technical know-how.

Pride in the finished result

At the end of an afternoon rich in variety the finished workpiece finally stood: a pizza cutter. To be able to hold it in their own hands and as the reward for several hours of committed project work to take it home with them gave the students a tremendous sense of achievement which absolutely delighted them.