Sash parts

TITAN timber

In order to achieve more with fewer components, quality is key. With TITAN,

this is invested in unique product details such as the tried and tested comfort mushroom cam and

the click-on coupling feature with fine toothing. But it also shows in every work step

that is simplified or even omitted, thanks to TITAN. The clever system concept

tightens your logistics and will lead you more quickly to success.

Gear

Sets new comfort and security standards with ease.

State-of-the-art TITAN gears set new standards with ease. In combination with TITAN comfort mushroom cams they are pivotal for permanently high ease of use and consistent intruder resistance – but also the key to appreciably greater efficiency. Because thanks to their tolerance-insensitive clamping all components can be screwed on perfectly automatically and permanently seated precisely and tightly.

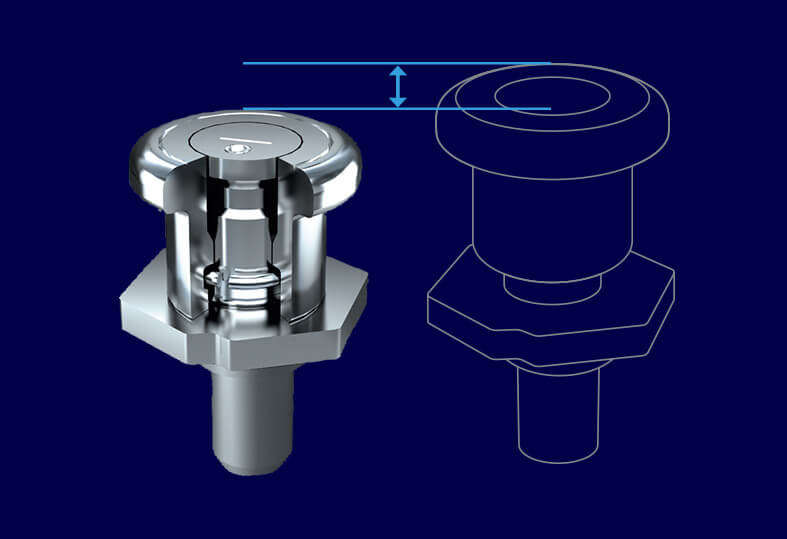

TITAN comfort mushroom cam

Automatic tolerance compensation.

- continuous height adjustment: automatically equalises air-gap tolerances and changed frame conditions, such as temperature fluctuations, and simplifies installation

- maximum ease of use thanks to a durable and effortless locking system that is optimally adjusted at all times

- effective system structure with the TITAN comfort mushroom cam: fewer components and less warehousing for solutions up to RC2 and more

- High intruder resistance can be achieved

Corner drive

TITAN tilt points

Tilt point with integrated sash lift.

Even the basic version sets a high standard. The slider is always perfectly supported on the bottom rod of the frame, thus automatically offsetting the production tolerances. The self-adjusting comfort mushroom cam serves as a locking pin that enables consistently optimised adjustment of the window.

Tilt point with sash lift and sash lift roller in the frame part.

Lifting the sash gently and early reduces the abrasion marks on the frame part to an absolute minimum. The low number of screw points – as with all TITAN tilt points – ensures fast production processes. Extra operating safety is guaranteed by the optional mishandling device, which is also offered preassembled – for even more efficient production processes.

Tilt point with sash lift arm.

The most effective sash lifter in the industry is especially well suited to large, modern windows. Heavy sashes are lifted early and discreetly and then closed gently. The visual effect on secondary sash elements is striking: the two sashes are always exactly aligned with each other. The integrated mishandling device facilitates comfortable and reliable operation.

TITAN click-on coupling points

For all installation technology.

If necessary, linkages and extensions on the bottom side and hinge side can be installed on the pre-weld profile. When installing on the finished sash, simply slide underneath the corner drive to enable quick positioning. The fine toothing with a 1.5 mm tooth pitch and large coupled bevels guarantees a reliable and precise joint with minimal play in the coupling. RC1 and RC2 versions can be achieved without additional cropping processes.

Clamping

Insensitive to tolerances and suitable for automated screwing.

All sash components feature efficient groove clamping. Since all components are reliably clamped, the screwing process can be automated without any problems. This guarantees lasting secured positioning of the hardware components.

Stay

Tightens better, brakes more smoothly.

- reduced stay thickness allows for improved tolerances

- optimal tilt stay lead-in to close even wide sashes with ease

- greater load-bearing capacity and comfort with minimum wear: high-quality PVC sliders and standard friction bushings for a smooth slide to the tilt position

- integrated anti-slam device in the tilt position, which also cushions the stop

- shift interlock in tilt position prevents misuse